Interview 企業インタビュー

heiwashoji kk.

平和商事株式会社

あらゆる事態が起こりうる現代社会。状況に応じた感染症BCP策定で、企業の持続可能性を高めていく。

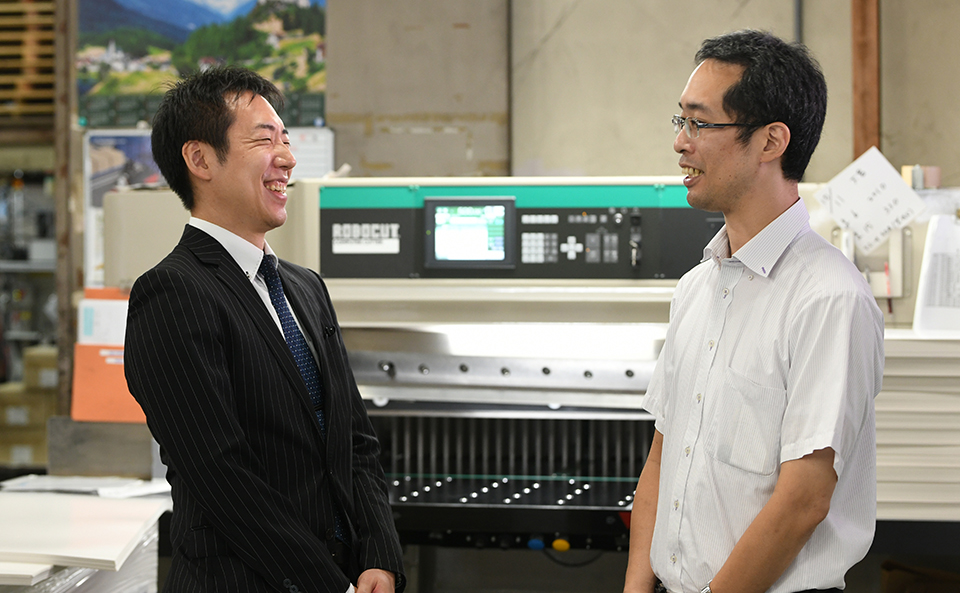

竹前 友勝 TAKEMAE Tomokatsu

平和商事株式会社 代表取締役

1981年東京都荒川区生まれ。大学卒業後、ゲーム会社に入社。

その後父が経営する平和商事株式会社へ移り、2012年に代表取締役に就任。

CEO, heiwashoji kk.

Born in Arakawa Ward, Tokyo in 1981. After graduating from university, he joined a video game company. Afterwards, he switched to working at heiwashoji kk., which was run by his father, and then became CEO in 2012.

持続的な成長を目指すうえで感染症BCPは欠かせない

贈答用の菓子や文房具を入れる函や、洋菓子店で使うケーキを持ち帰る用の函など、紙器容器の企画・製造・販売を行う平和商事。3代目代表取締役として従業員11名をまとめ上げる竹前代表が考える、感染症BCPの目的や位置づけとは――。

竹前「ひとことでBCPといっても、自然災害や内外の要因など、意識することはさまざまです。広範囲に被害が及び、復旧に時間を要する自然災害に対し、感染症の被害範囲は主に社内のみ。10日間程度で事態が収束するなど、性質が全く異なります。だからこそ、それぞれに応じた対策が必要。BCPは、会社を成長させ、維持するために不可欠なものです。平常時からBCPを整備することで企業の地盤を固めるとともに、新規顧客の開拓や取引の多角化などで利益率を高め、事業の成長を維持したいと考えています」

BCPを策定している中小企業の割合はわずか6社に1社程度。一般的なBCPに加え、災害用のBCPを整備することで、一歩先を行く経営を目指したいと、竹前さんは熱を持って話します。

情報共有×マッピングで非常事態に立ち向かう

企業の成長維持のために、BCPは大いに役立つと語る竹前さん。かつての経験から、社内での情報共有を第一に考えて、感染症BCPを整備したそうです。

竹前「新型コロナウイルス感染症(COVID‑19)が猛威をふるっていた2022年の夏ごろ、従業員3名が感染。当社の従業員は11名ですから、3人が休むだけでも、生産総量は単純計算で4分の3になるうえ、そのうちの1名は工場長。彼らの自宅待機期間中の業務采配には非常に苦労しました。その経験を活かし、誰が休んでも業務がスムーズに回るよう、ノウハウやスケジュールを社内で逐一共有しています」

また、感染症BCP整備においては、クライアントのリストアップも重要なのだとか。

「クライアントごとに作業内容や受注金額、納期などをまとめたリストを作成しました。洋菓子店や金属加工会社など、通年で付き合いがある会社は約250社。それぞれの構成比と粗利をもとに各企業をマッピングすれば、どのクライアントを優先すべきかが見えてきます」

非常時にはスケジュールとマッピングとを照らし合わせ、実際に優先度の高いクライアント向けの製品の製造が間に合わない場合は、協力会社や同業他社へ作業を依頼。緊急性の低いクライアントには納期延長を打診するなど、状況に応じた対策を考えているのだと、竹前さんは語ります。

さらなる発展を目指して自社に合わせた感染症BCP策定を

感染症BCPの策定を一通り終えた平和商事は、自社なりのアレンジを加える段階へと進んでいます。

竹前

「業務内容や形態、従業員の数など、企業の状況に応じたBCPを整備することで、さらなる成長が期待できます。当社に必要なのは、工場長のように、替えのきかない人材がダウンしてしまった場合の対策。個々人の能力も踏まえながら、平和商事ならではのBCPを整備していきたいです」

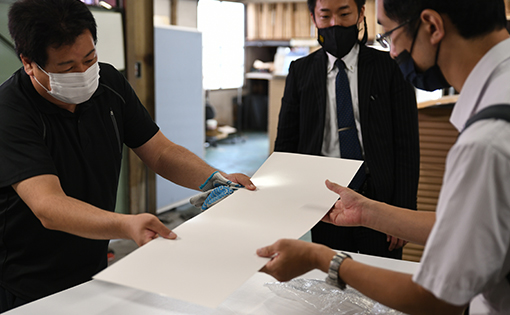

平常時は一人が1種類の機械を受け持つ形で函を製造するスタイルをとっている平和商事。機械の特性もさまざまな中で、担当者以外もそれぞれの機械を動かせるようにレクチャーしているそうです。

自然災害から感染症被害まで、あらゆる事態が起こりうる現代社会。緊急事態に備えて、平常時からできる限りの準備をしておくことが、企業の持続的な発展につながります。思わず手に取りたくなるような魅力的な函づくりを目指して、竹前さんと平和商事のさらなる成長は続きます。

English

In today’s society, all kinds of situations can occur.Businesses can enhance their corporate sustainability by formulating a BCP for infectious diseases tailored to the situation.

A BCP for infectious diseases is an essential component for achieving sustainable growth

heiwashoji plans, manufactures, and sells a range of paper containers, such as boxes for holding confectionery and stationery for gifts, as well as boxes used in confectionery stores for taking cakes home. Here, Mr. Takemae, third-generation CEO of a company with 11 employees, discusses the purposes and significance of BCPs for infectious diseases.

Takemae:

In a nutshell, BCPs are based on a variety of factors, including natural disasters and internal and external factors. In contrast to natural disasters, which can cause damage over a wide area and require time for recovery, infectious diseases mainly affect only the company itself.

Infectious diseases are by nature quite different. For example, in some cases, the situation can be resolved in a matter of ten days. Therefore, each requires its own set of countermeasures. A BCP is essential for the growth and maintenance of a company. By developing a BCP as part of our routine work in anticipation of an incident, we hope to solidify the company’s foundations, increase profit margins by cultivating new customers and diversifying our business dealings, and maintain business growth and improve our credibility as a company.

Only about one in six SMEs have a BCP in place. Mr. Takemae speaks enthusiastically of his desire to stay one step ahead in management by developing a BCP for disasters in addition to a general BCP.

Confronting emergencies through information sharing and mapping

Mr. Takemae says that a BCP is very useful for maintaining the growth of a company. Based on his past experience, he has developed a BCP for infectious diseases, with information sharing within the company as the first priority.

Takemae:

Around the summer of 2022, when the COVID-19 pandemic was raging across Japan, three of our employees became infected. Since we have 11 employees, even if three employees were to take a day off, the total production volume would be reduced by three quarters in a simple calculation. On top of this, one of them was the plant manager. It was very difficult for us to coordinate operations during the period they were on leave. Based on this experience, we now share our know-how and schedules within the company to ensure that operations run smoothly, even if anyone takes a day off.

In addition, it is also important to create a list of clients when developing a BCP for infectious diseases.

Takemae: We list and order the work and priorities for each client. There are approximately 250 companies that we work with throughout the year, including confectionery stores and metalworking companies. By mapping each company based on their respective composition and gross profit, we can see which clients should be prioritized.

During emergencies, Mr. Takemae’s company compares the schedule with the mapping, and if it is unable to manufacture a product for a high-priority client in time, it outsources the work to a subcontractor or other company in the same industry. For non-priority clients, Takemae passionately explains that they consider countermeasures according to the situation, such as asking for an extension of the delivery date.

Formulate an infectious disease BCP tailored to your company with a view to further development

Having completed the formulation of its infectious disease BCP, heiwashoji is now in the process of making its own arrangements.

Takemae:

Further growth can be expected by developing a BCP that is appropriate to the company’s situation, such as the nature and form of the business and the number of employees. What we need is countermeasures in the event that irreplaceable personnel, such as the plant manager, go down. I would like to develop a BCP that is unique to heiwashoji while also taking into account the abilities of each individual employee.

Usually, heiwashoji’s style of manufacturing boxes is to have one person is in charge of one type of machine.

However, the company gives lectures on the various characteristics of the machines so that people other than the person in charge can also operate each machine.

From natural disasters to infectious disease outbreaks, all kinds of situations can occur in today’s society. Being as prepared as possible for emergencies, even under normal circumstances, will lead to the sustainable development of your company. Aiming to create attractive boxes that people will want to pick up without a second thought. The further growth of Mr. Takemae and heiwashoji will continue.

- 白山キャンパス

- 〒112-8606 東京都文京区白山5-28-20

- 赤羽台キャンパス

- 〒115-8650 東京都北区赤羽台1-7-11

- 朝霞キャンパス

- 〒351-8510 埼玉県朝霞市岡48-1

- 川越キャンパス

- 〒350-8585 埼玉県川越市鯨井2100